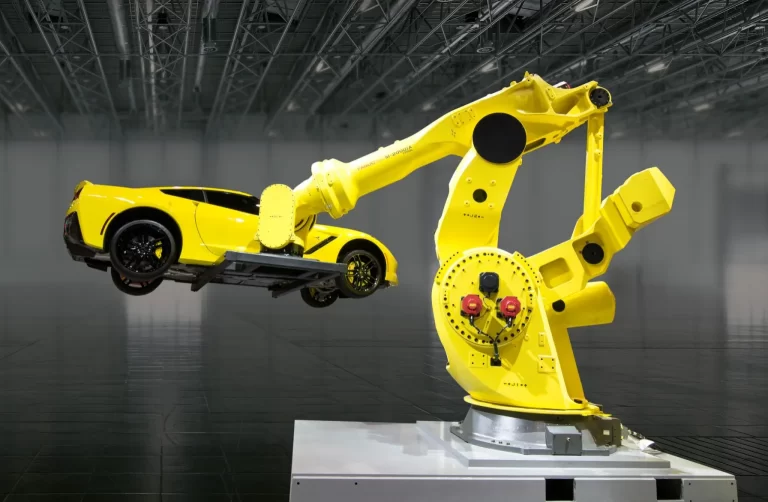

Robotic arms, at the heart of modern manufacturing and production have been transforming the rules in a way that was previously not possible. They are able to combine accuracy, safety and efficacy. These amazing machines – commonly called robot arms been a necessity for industries all over the world motivated by the need to cut costs without sacrificing quality. Robotic arms are being integrated into production lines to lower expenses and enhance security. Let’s explore how these innovative machines are reshaping the industrial landscape.

Image credit: automatedsolutions.com.au

The primary force behind the increase in global robotic arm usage is efficiency in cost. Factory owners are constantly under the pressure to decrease workplace injuries, minimize production mistakes, and reduce production waste. Robotic arms are designed to combat these challenges. Robot arms are more accurate than human laborers when it comes to completing repetitive tasks, reducing the amount of waste and avoiding costly mistakes. In industries with high volumes, such as automotive manufacturing, robotic arms ensure flawless assembly by performing precise welding and parts placement. This accuracy can translate into significant savings as less defective products means less work and wasted.

Safety is a second cornerstone in the revolution of robotic arms. Many manufacturing tasks such as handling dangerous materials or operating machines that are heavy pose a risk for human workers. With the help of robot arms, firms can shield employees from hazardous environments, significantly decreasing the risk of workplace injuries. Robotic arms, constructed as a chain of joints which move, could mimic the function of human arms without causing physical damage. These machines are equipped with robotic hands, or end-effectors that can be programmed. They can perform tasks such as grasping, spinning, and welding in conditions that make it dangerous for humans.

The versatility of robotic arms makes them a game-changer across diverse industries. From automotive assembly to electronics production, robot arms adapt to a broad range of tasks. The programability of these arms allows them to perform complicated tasks such as painting or applying fiberglass at an unparalleled degree of precision. Robotic arms have revolutionized the process of palletizing in warehouses, automating it with speed and precision. The automation increases productivity and the reliability of robots as they work continuously and never get tired.

Cobots are an entirely new breed of robots that work in tandem with humans. Cobots, equipped with a robotic arm, can interact seamlessly with humans unlike industrial robots which are usually confined to cells. The hands of a robot can be utilized for difficult lifting tasks and repetitive tasks in factories, so that human workers are freed to take on more challenging duties. The collaboration improves productivity as well as ensures a safe workplace, since cobots can be programmed to alter or stop their actions when someone is nearby.

The significance of robotic arms goes beyond safety and efficiency, to the structure of manufacturing today. They are crucial for industries that require extreme precision in processes such as welding, assembly or material handling. For example, in manufacturing of automobiles, a robot arm is able to rotate and move components during assembly, ensuring flawless alignment, without the intervention of humans. Robots are also utilized in electronics to take care of fragile components. This prevents damage and also improves the quality of output.

Robotic arms are predicted to grow in importance as industries grow. As they can reduce costs, improve safety and adapt for different tasks robotic arms will be essential to the future of manufacturing. Combining cutting-edge technology with human ingenuity, robot arms are not only tools, they are partners in development, accelerating innovation and revolutionizing the way we create the world around us.